Information about our stainless steel sinks, taps and accessories

We at The Kitchen Sink Ltd strive to improve the variety and range of products at all times. The Kitchen Sink Ltd reserves the right to change the range of products at any time.

Prices listed are quoted including VAT at the current rate.

Sink and tap colours and finishes shown are for reference only. “Reversible” sink means that the sinks may be situated with the drainer either on the left or right hand side. If a sink is left hand drainer or right hand drainer it is important to specify the required version when placing an order.

Measurements are in millimetres. Any technical drawings are for illustrative purposes only and are not meant as cut-out templates. Pdf files or their equivalent are available in most cases.

Using a professionally qualified plumber is recommended when fitting a new kitchen sink and/or tap.

The standard hole diameter required in the countertop for a monobloc kitchen tap is almost 35mm or 1 3/8th inches. It is always best to check and we recommend you have the tap and/or sink before you cut your countertop. Some cold water filter taps and bridge mixer taps may require smaller tap holes.

Sink cut-out recommendations from suppliers may be recessed back from the sink, flush with the edge of the sink, or overlapping the edge of the sink. Always check with your counter fitter which is your preference. If you wish to use sink accessories such as colanders or chopping boards, please inform your stone mason or kitchen design studio before the countertop is cut.

Maintaining and caring for our sinks & taps could not be easier. We recommend the following guidelines in order to prolong the life and look of our sinks and taps. Please click on each section to reveal further information:

Caring for your quality stainless steel sinks, taps and accessories

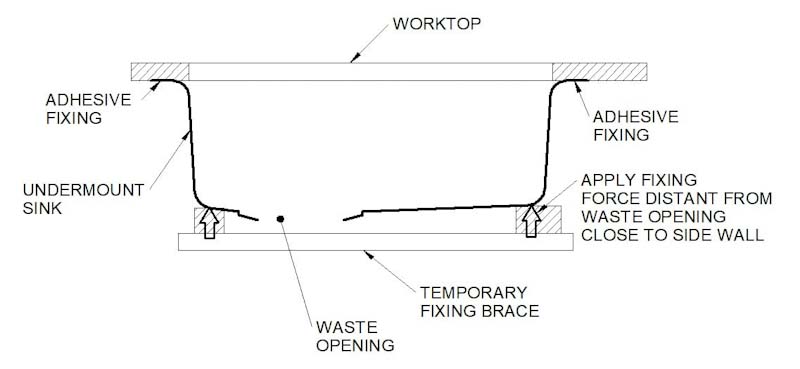

Fixing undermount sinks to your countertop

When adhering your sink to your countertop, it is recommended that care is taken and pressure is not put on the underside of the sink near the waste opening, as this will result in the base of the sink becoming flatter than designed and may result in water not draining from the sink correctly. Please see our diagram below. Similar care should be taken when installing flush-mount and top-mount/inset sinks.

Caring for ceramic sinks

Care should be taken not to place extremely hot pans or utensils into or onto your sink. Scorching or scald marks might result, which could be permanent. These marks are very difficult to remove as they damage the surface material of the sink. One suggestion to remove scorch and burn marks is to use fine sandpaper to remove the top layer of the sink surface. This applies whether the sink is ceramic, composite quartz or stainless steel.

PVD Coating on Colour Coated Kitchen Sinks & Taps

Information about the PVD surface on copper sinks

PVD is a super-hard coating. PVD Coating adheres best to chrome plated materials and stainless steel. Some materials are not electroplated and the PVD coating is applied directly to the substrate material (Titanium alloys and Graphite). Provided the material is thoroughly chrome plated with Nickel/Chromium almost any material can be PVD coated. The PVD coating thickness is usually between 0.25 microns and 5 microns for decorative finishes. Thicker coatings can be applied for functional coatings. The lifetime Brass finish is Zirconium Nitride (ZrN) and has a hardness of 2800 Vickers or HRc-80.

Cleaning Colour Coated Sinks and Taps

PVD Maintenance is simple. You can use a soft cloth with mild soap and water. Avoid all products designed to remove tarnish or rust, any products that contain hydrochloric, hydrofluoric, and/or phosphoric acid or caustic agents. If using cleaners containing bleach, wash off within ten minutes. If using plughole un-blockers, wash off within 15 minutes. Many foods and liquids can be corrosive, such as salt, vinegar, alcohol, fruit juice, mustard, mayonnaise etc. Make sure to wash these off within 15 minutes. Any strong chemicals should be washed off immediately. Avoid scouring pads, silver cleaners and abrasive powders. If in doubt test your cleaning product on the underside of the sink before using on the surface.

Kitchen utensils made of carbon steel without a protective surface should not be left in the sink as they may deposit iron particles, which develop into rust stains over time.

Returns policy

Should you change your mind after having purchased the product and wish to return it, we will accept the item provided it is in perfect condition and in its original packaging. There will be a restocking charge. This charge will be 30% of the sale price of the goods. Return of the goods will be the responsibility of the purchaser.

Tap and sink warranty

Understanding water pressures and bar rating for taps

When fitting a new kitchen tap, water pressure can be a very important factor in choosing which products will be suitable. Normally, the cold water pressure doesn’t present a problem as this should be at the pressure of the mains, but the pressure of the hot water must be taken into consideration when deciding which tap style to choose. This is because a tap that is designed for a high pressure water supply could take a long time to fill a sink or saucepan if it is fitted on a gravity fed system in a single storey home.

The water pressure available in a gravity fed system is directly related to the height of the cold water storage tank. Water pressure can be measured in three common units, bar, psi and Head(m).

1 bar = 10 metres Head = 14.5 psi.

To calculate the available pressure simply measure the distance, in metres, from the bottom of the cold water tank to the outlet (end of the spout) of the tap and multiply by 0.1 – this will calculate the pressure in bar. Every metre height of water = 0.1 bar of pressure. Kitchen taps with a bar pressure of 0.5 or less should work very well in a gravity fed system of a standard two storey home with the tank in the attic, provided the plumbing is also of standard size.

Caring for your wooden chopping board

Do not soak your wooden chopping board or any other wooden utensils of they will crack and warp. Generally, all that is required is a good scrub with hot soapy water. After cutting raw meat it may be advisable to use a diluted bleach solution to scrub the board. Other alternatives for cleaning include a mixture of lemon juice and salt. Putting your wooden chopping board in a dishwasher is not recommended.

Once a month, to maintain the surface and prevent the wood from drying out, it is recommended that the wood is oiled, using linseed oil or mineral oil combined with beeswax or ready made treating oils available in hardware stores. Make sure the board is thoroughly cleaned and completely dry before oiling. Leave them for a few hours and then wipe off any excess oil. More maintenance tips are available on the internet.

Dual Flow and Single Flow Taps

In a single flow tap, the hot and cold water mix within the body of the tap and spout. In a dual flow tap, the hot water and cold water are kept separate the whole way through the tap. The hot travels through a small tube inside the spout and the cold water travels in the area between this tube and the outside spout.

Having a dual flow tap means that should your water supply be disrupted, your fresh cold water is protected from back-flow from the hot water that sits in the tank. It also keeps the spout from getting too hot and can protect from burns. Generally, dual flow taps perform well in low water pressure situations. Because of this design, there is no facility to fit a water diffusing aerator at the end of the spout.

Sometimes, a small amount of water stays in the spout after the tap is turned off. It then drips out a few seconds later. This happens because of capillary action until gravity takes over.

Tap aerators work by adding air to the water flow. This will slightly reduce the water flow rate, but they can make the flow more even and reduce splashing.

Recommendations for Wheelchair Accessibility

Below please see an excerpt from the recommendations for wheelchair accessibility in relation to kitchen sinks and taps. The Alveus Basic 10 and the Alveus Basic 170 sinks meet these depth requirements and are very modestly priced. We also stock an extra-long handled tap called the Omega Extended Lever, for ease of reach.

“The kitchen sink should be inset with a shallow bowl that is 140mm to 150mm deep. The worktop adjacent to the bowl should be a minimum of 500mm wide. The underside of an exposed sink should be heat insulated to avoid the possibility of burns to knees and legs. There should be clear knee recess under the sink that is not less than 900mm wide. Any fascia should be no deeper than the projection of the bowl below the worktop. A swivel neck mixer tap, with clear markings to indicate hot and cold settings for the benefit of visually impaired people, should be fitted to the sink within easy reach of wheelchair users, if necessary, at the side of the sink bowl. The tap should have a quarter turn lever operation from off to full water flow.”